In industrial automation and manufacturing, every connection counts. The ability to reliably and efficiently transfer data, signals and power is critical to seamless operation. This is where the M12 connector comes into play. These small but powerful connectors have revolutionized the way machines communicate, offering a wide range of benefits and applications. In this blog, we explore the versatility and importance of the M12 connector in the modern industrial environment.

M12 Connectors: A Brief Overview:

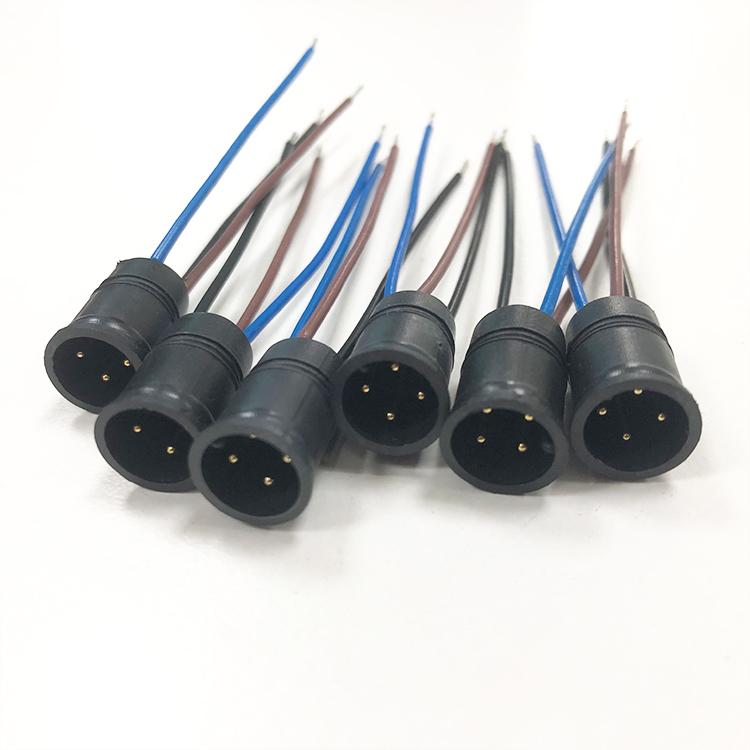

M12 connectors are circular connectors commonly used in industrial automation, robotics, and sensor applications. Designed to withstand harsh environments, they provide a reliable solution for connecting a wide variety of devices and appliances. These connectors are available in different pin configurations including 4, 5 and 8 pins for versatility in different applications.

Advantages of M12 connectors:

1. Reliability: M12 connectors are known for their robustness and resistance to environmental factors such as moisture, dust and vibration. This reliability ensures uninterrupted performance, which is critical in industrial environments where machines need to operate continuously.

2. Easy installation: The standardized screw locking mechanism of the M12 connector can realize fast and safe connection. This ease of installation reduces downtime during installation or maintenance, increasing overall productivity.

3. Wide range of applications: M12 connectors can be used in various industries, including automotive, food processing, machine tools and manufacturing. From transmitting power and signals to enabling data communication, these connectors can be easily adapted to different requirements.

M12 connector type:

1. M12 A-coded: M12 A-coded connectors are designed for data communication and support Ethernet and Profinet protocols. They ensure high-speed data transmission over long distances, making them ideal for applications requiring fast and reliable network connections.

2. M12 D-coded: M12 D-coded connectors are designed for fieldbus applications such as DeviceNet and CANopen. They provide efficient communication between sensors, devices and controllers in industrial networks.

3. M12 X-Coded: The M12 X-Coded connector has a robust design and higher data transfer capability for industrial Ethernet applications such as EtherCAT and EtherNet/IP. They are ideal for harsh environments requiring high bandwidth and precision.

4. M12 power connector: In addition to data transmission, the M12 connector also supports power transmission. M12 power connectors are available in a variety of pin configurations to ensure efficient power distribution to devices, reducing the need for separate power cords.

M12 connectors are an integral part of modern industrial applications due to their reliability, ease of installation and adaptability to different requirements. Whether transmitting data, power or signals, these connectors provide a versatile solution that ensures seamless communication between devices and enables efficient automated processes. As the industry continues to evolve and demand higher performance, M12 socket connectors will continue to play a vital role in shaping the future of industrial automation.

Post time: Aug-02-2023