Many of our customers have provided feedback to us, often citing issues they’ve encountered with their previously purchased terminals. Today, I will provide you with a comprehensive response.

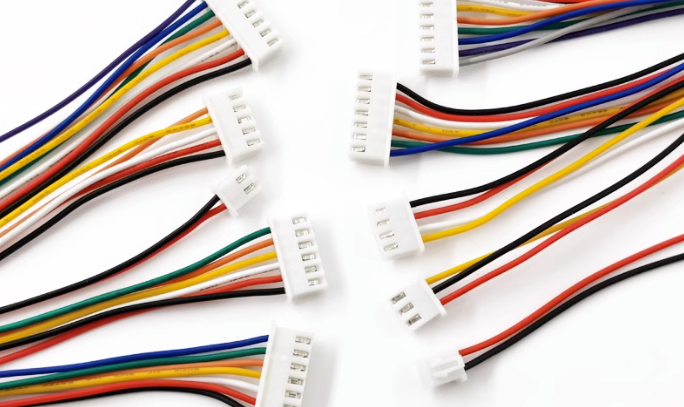

①Many enterprises have been relying on a single supplier for an extended period of time, resulting in frequent delivery delays and unstable product quality. Have you ever encountered such a situation? In this case, it is necessary to consider developing alternative backup suppliers. Although the terminal line may seem like a small spare part, its quality directly impacts the overall performance of the product. Purchasing inferior terminal lines at a cost of one or two cents can lead to undesirable after-sales consequences and negative impact.

②A customer have complained with me, there were instances where the wire purchased would not conduct electricity due to incorrect polarity. This recurring issue is attributed to the fact that most terminal wires available in the market are manually threaded and have not undergone thorough testing, resulting in inevitable reverse wiring.

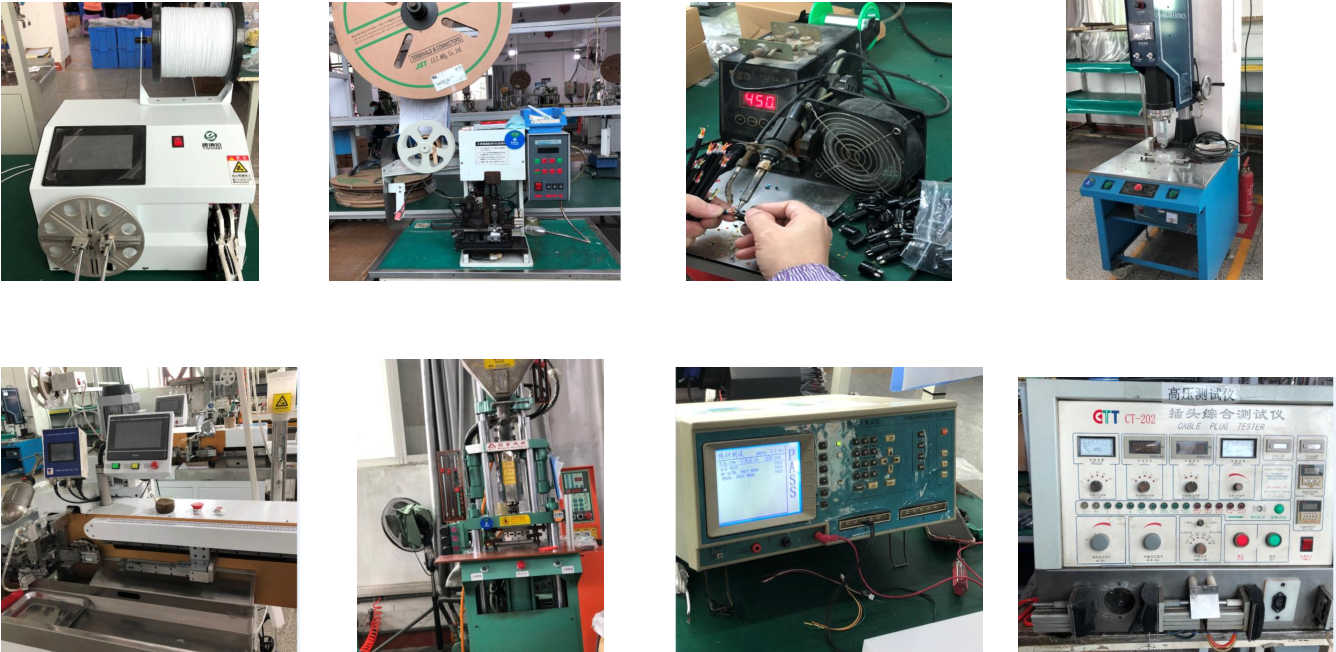

However, if fully automated machines are utilized for shell threading and each wire undergoes meticulous inspection, such errors can be avoided. If a fully automatic machine is used to thread the shell and every wire is tested, there will be no incorrect wear.

③There are also some quality issues, such as poor contact between wires and broken wire insulation. However, if your supplier conducts thorough inspections, these problems can be prevented.

Changjing Electronic Technology Co., Ltd. is a leading manufacturer of terminal wires with 10 years of experience in production, equipped with over 20 sets of fully automated production equipment that enable us to achieve a daily output of up to 10W. Our products have undergone rigorous quality inspections and are certified by UL and ROHS for environmental protection, ensuring peace of mind for our customers when customizing their orders.

Post time: May-17-2023