In the fast-paced world of automotive advancements, staying connected has become a must for drivers and their vehicles. One of the many innovations brought about by the convergence of automotive and electrical engineering is the use of printed circuit board (PCB) connectors in cars and motorcycles. These connectors play a vital role in enhancing connectivity, improving functionality and ensuring a safe and reliable driving experience. In this blog, we will delve into the importance of electrical PCB connectors in automobiles and motorcycles.

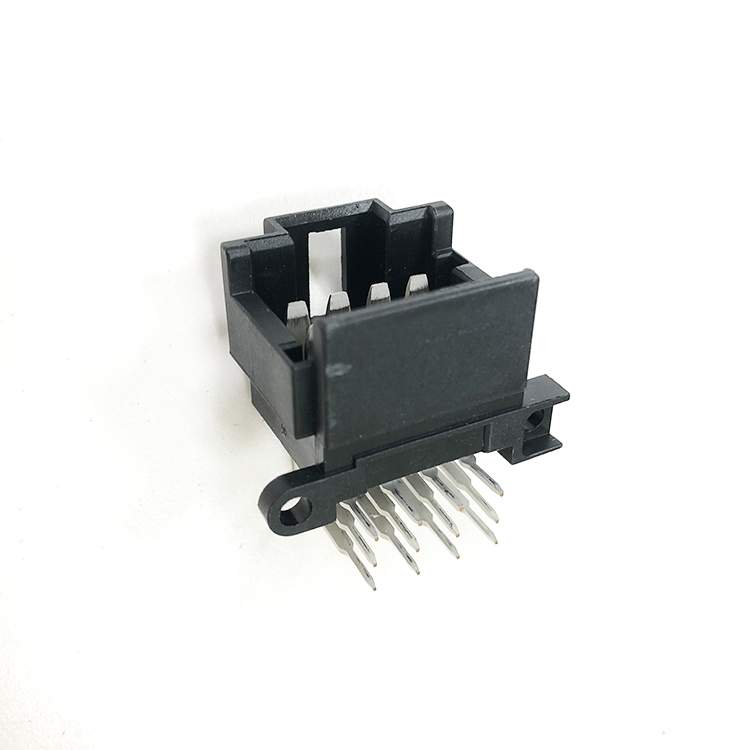

1. Efficient electrical signal transmission:

Efficient electrical signal transmission is at the heart of automotive connectivity. PCB connectors are specifically designed to provide reliable and secure connections between various electronic components in vehicles such as sensors, control units and displays. By ensuring seamless transmission of electrical signals, these connectors prevent data loss or corruption, enabling optimal performance and enhancing road safety.

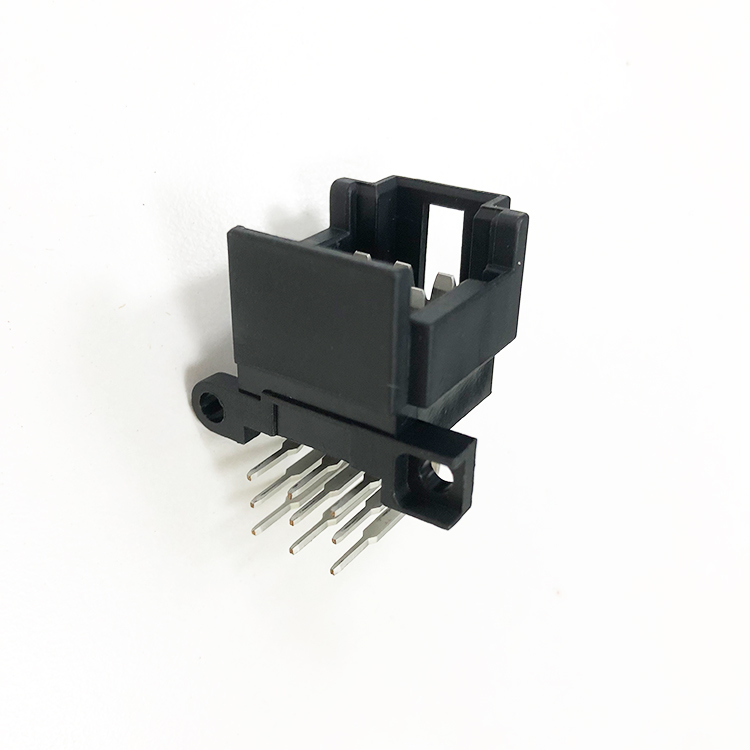

2. Compact design and space optimization:

Cars and motorcycles often operate in environments with limited space. The compact design of PCB connectors utilizes space efficiently and ensures optimal functionality of electronic systems without compromising vehicle design. These connectors can be seamlessly integrated into existing electrical systems for easy installation and maintenance.

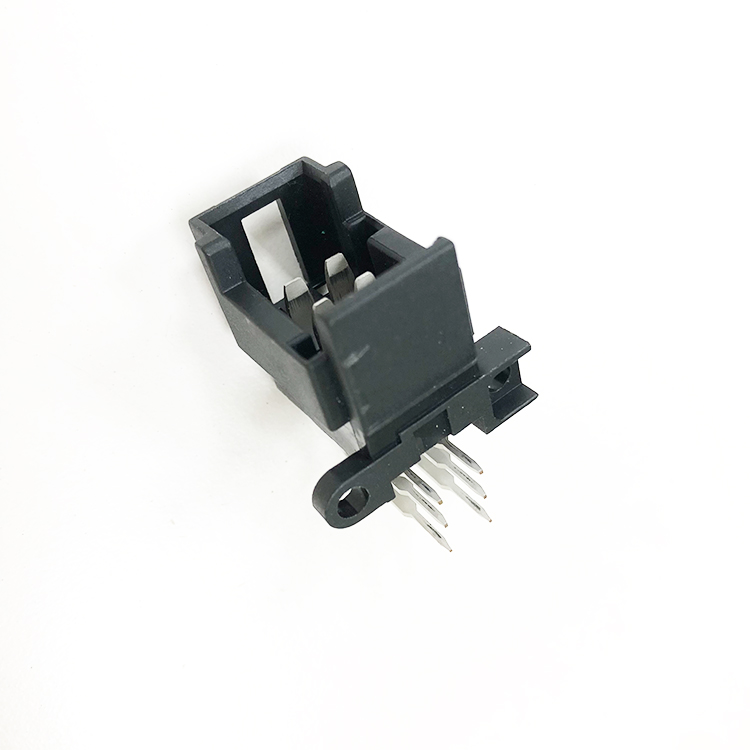

3. Vibration resistance and durability:

Vehicles are often subjected to vibrations and shocks on the road. PCB connectors are able to withstand these challenging conditions, ensuring a secure electrical connection regardless of external interference. These connectors are robustly constructed with excellent vibration resistance for reliability and long life.

4. Customization and flexibility:

A wide variety of automotive electrical systems require connectors that can be customized to meet specific requirements. PCB connectors offer flexibility in design, contact arrangement, and pin configuration, making them suitable for a variety of automotive applications. This flexibility ensures seamless integration into complex electrical systems, enabling efficient connectivity and improving overall vehicle performance.

5. Enhanced security features:

Safety is of paramount importance in the automotive industry and electrical PCB connectors make a significant contribution to the implementation of advanced safety features. These connectors facilitate the integration of cutting-edge safety systems such as anti-lock braking systems (ABS), electronic stability control (ESC) or advanced driver assistance systems (ADAS). By enabling efficient transmission of critical signals, these connectors play a vital role in ensuring the effectiveness of safety features and improving overall driving safety.

6. Evolving Connectivity:

As the automotive industry moves toward the era of smart, connected cars, electrical PCB connectors become even more important. Vehicles of the future will rely heavily on advanced connectivity, including wireless communications, GPS and autonomous driving capabilities. PCB connectors will serve as the backbone of these functions, enabling seamless communication between various vehicle components and external systems.

The integration of electrical PCB connectors in automobiles and motorcycles has revolutionized automotive connectivity technology. With efficient signal transmission, compact design, durability, flexibility and contribution to advanced safety features, these connectors ensure a safe, secure and connected driving experience. As the industry continues to evolve, we can expect more complex and advanced automotive electrical PCB connectors to drive the future of automotive technology.

Post time: Jul-18-2023